Zibo City, Shandong Province

Have You Any Quires ?

10 PM – 6 PM

Zibo City, Shandong Province

Have You Any Quires ?

10 PM – 6 PM

Have You Any Quires ?

Continuously monitoring factory performance is, in my professional experience, the single most important factor in a long-term sourcing strategy, yet it’s the one most often overlooked. It’s a question I get constantly: ""My first order was perfect, but how do I know the quality will hold up?"" It is a completely valid concern. A great start means nothing if standards begin to slip by the third or fourth production run, a phenomenon known as quality fade (#footnote-1){#ref-1}. This is where your sourcing agent must prove their value not as a one-time matchmaker, but as your consistent, on-the-ground partner.

So, how can you be sure this is happening? You need to understand the mechanisms of professional oversight. This guide will break down the ten core methods I use to ensure the factories I select not only start strong but stay strong. We will explore everything from data-driven analysis to the strategic use of unannounced inspections.

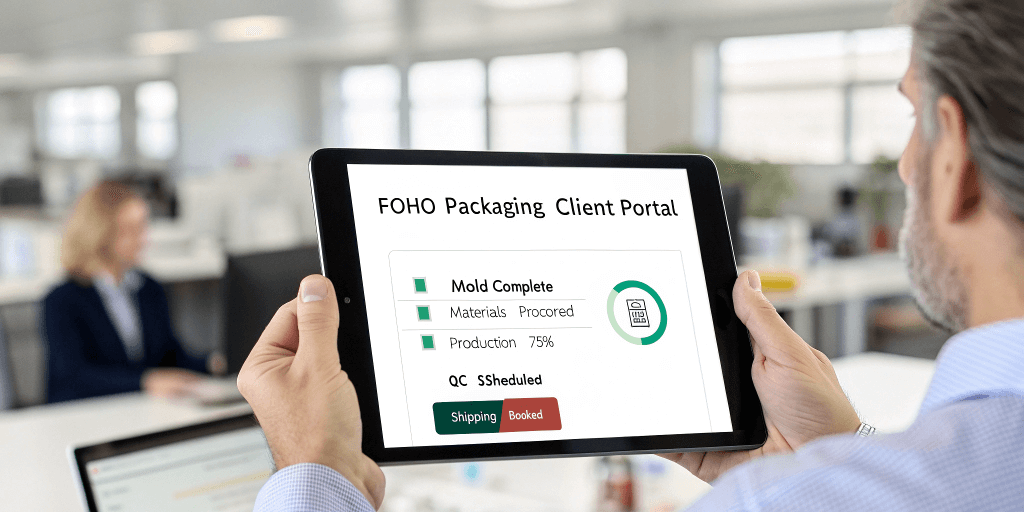

In modern supply chain management, waiting for a quarterly report is too slow. I insist on integrating real-time data collection wherever possible. This allows us to spot negative trends and deviations from the standard before they become major problems.

A common question I’m asked is, ""How often should we audit?"" The answer isn’t a fixed date; it’s a dynamic schedule based on risk. A high-performing, long-term partner may not need the same level of scrutiny as a new factory producing a complex product.

An audit is more than just a quick walkthrough. It’s a systematic investigation. My process is thorough and designed to get a true picture of the factory’s current operational reality.

To keep everyone accountable, I utilize supplier performance scorecards (#footnote-5){#ref-5}. These are shared documents that track key metrics against agreed-upon targets. They transform subjective feelings into objective data, making conversations about performance fact-based and productive.

While scheduled audits are essential for deep dives, nothing reveals a factory’s true daily reality like a surprise audit. This is a tool I use when I need to verify that standard procedures are being followed consistently, not just when an inspection is planned.

For critical projects, I recommend a layered audit approach. This means different levels of inspection happen at different frequencies, creating a web of oversight that ensures continuous compliance.

With today’s technology, continuously monitoring factory performance doesn’t always require an expensive plane ticket. We can leverage digital tools to maintain a high level of oversight remotely, making the process more efficient and cost-effective.

The audit schedule I create at the start of a partnership is never set in stone. It must be a living document, adjusted dynamically based on the factory’s real-world performance.

All the monitoring in the world is useless if the information doesn’t reach you, the buyer, in a timely manner. I establish clear communication protocols (#footnote-8){#ref-8} from day one to ensure you are always informed of any significant developments.

It’s worth emphasizing this point again. Unannounced inspections, or surprise audits, are one of the most powerful tools in my arsenal for ensuring long-term, consistent quality. They are the ultimate test of a factory’s commitment to your standards.

This table provides a general framework for how I approach audit frequency based on a supplier’s risk profile.

| Supplier Risk Level | Performance History | Recommended Full Audit Frequency | Ongoing Monitoring Methods |

|---|---|---|---|

| High | New supplier, past quality issues, complex product | Annually | Monthly Scorecards, LPAs, potential Surprise Audit |

| Medium | Consistent but with occasional minor issues | Every 18-24 Months | Quarterly Scorecards, Remote Video Checks |

| Low | Long-term partner with excellent, stable record | Every 3-5 Years | Annual Scorecard Review, open communication channels |

When you engage a sourcing agent, it’s crucial to have a direct conversation about their monitoring and evaluation process. Don’t be shy. You should be asking specific, probing questions based on the strategies I’ve outlined above. Ask to see a sample audit report or a supplier scorecard. A professional agent will not be defensive; they will welcome your diligence and see it as the foundation of a strong partnership. The goal is to establish a clear Service Level Agreement (SLA) (#footnote-10){#ref-10} that defines the monitoring activities they will perform on your behalf, ensuring there are no ambiguities about your expectations for ongoing oversight.

Continuously monitoring factory performance is not about mistrust; it’s about maintaining excellence. It transforms the client-supplier relationship from a simple transaction into a dynamic, data-driven partnership. By understanding and insisting upon these monitoring strategies, you empower your sourcing agent to act as your true guardian of quality, ensuring that every production run is as good as the first. This proactive approach is the ultimate way to protect your brand, your customers, and your bottom line.

How often should my supplier’s factory be audited after our first order?

The frequency depends on risk. For a brand new supplier or a complex product, I recommend a follow-up audit within the first year. For a proven, low-risk supplier with a history of excellence, a full physical audit might only be necessary every 3-5 years, supplemented with continuous remote monitoring.

What does an ongoing factory audit process typically involve?

A typical audit involves a structured process: 1. Preparation: Reviewing past data and creating a checklist. 2. On-Site Inspection: A physical tour to check production lines, safety, and quality stations. 3. Documentation Review: Verifying licenses, certifications, and quality logs. 4. Interviews: Speaking with staff. 5. Reporting: A final report with findings and a required corrective action plan for the factory.

How will I be informed if a factory’s performance starts to decline?

Your agent should have a clear communication protocol. I use a combination of automated alerts for KPI deviations, regular performance scorecards (usually monthly or quarterly), and a commitment to immediate personal communication (phone or email) within 24 hours of discovering any significant decline in quality or delivery performance.

Can I request a surprise audit on the factory producing my order?

Yes, absolutely. As the client, you have the right to request a surprise (unannounced) audit. I highly encourage it as a tool for ultimate verification. Simply coordinate with your sourcing agent to arrange the logistics. A good factory, while perhaps not thrilled about the surprise, will be accommodating and should have nothing to hide.

<span id=""footnote-1"">1. Understand the concept of quality fade and how it can affect your products. ↩︎

<span id=""footnote-2"">2. Explore key performance indicators (KPIs) commonly used in the manufacturing industry. ↩︎

<span id=""footnote-3"">3. Learn about the benefits and process of conducting unannounced factory audits. ↩︎

<span id=""footnote-4"">4. A guide to Corrective and Preventive Actions (CAPA) in quality management systems. ↩︎

<span id=""footnote-5"">5. Find templates and best practices for creating effective supplier performance scorecards. ↩︎

<span id=""footnote-6"">6. An in-depth explanation of Layered Process Audits (LPAs) and their benefits. ↩︎

<span id=""footnote-7"">7. Discover how to effectively conduct a remote factory audit using video technology. ↩︎

<span id=""footnote-8"">8. See examples and templates for creating a formal project communication plan. ↩︎

<span id=""footnote-9"">9. Read about the hidden dangers of unauthorized subcontracting in global supply chains. ↩︎

<span id=""footnote-10"">10. A clear definition of what a Service Level Agreement (SLA) is and why it’s important. ↩︎"

You can leave any questions. We will see and answer you.