Zibo City, Shandong Province

Have You Any Quires ?

10 PM – 6 PM

Zibo City, Shandong Province

Have You Any Quires ?

10 PM – 6 PM

Have You Any Quires ?

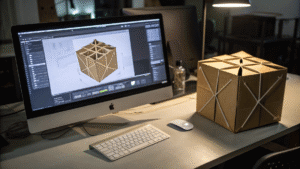

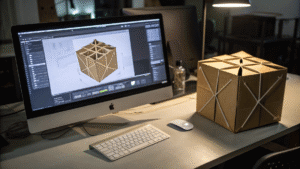

In my experience sourcing custom packaging for complex products, I’ve learned a critical lesson: a brilliant design file is worthless if your supplier’s technical team cannot execute it with precision. The gap between a CAD drawing (#footnote-1){#ref-1} and a flawless physical package is where most quality issues arise, leading to costly delays and budget overruns. This is why verifying a supplier’s true technical expertise, not just their sales pitch, is the most crucial step in the procurement process (#footnote-2){#ref-2}.

To help you avoid these pitfalls, I’ve developed a rigorous vetting framework. This guide outlines 10 actionable methods you can implement to ensure your supplier’s team has the required knowledge to understand and perfectly produce your packaging designs. Following these steps will help you secure a true manufacturing partner, not just a vendor.

Before diving deep, check the credentials of the team who will handle your project. In my experience, it’s best to require that key technical staff, like packaging engineers and production managers, hold specific industry certifications or relevant academic degrees. This provides a baseline assurance that they are familiar with industry best practices, materials science, and engineering principles.

Go beyond a standard factory tour. A formal technical audit (#footnote-3){#ref-3} should focus specifically on their workflow for handling design files. Review their documented process for interpreting technical drawings, translating CAD files into machine instructions, and their protocol for flagging potential design flaws. This reveals their operational discipline and attention to detail.

To eliminate ambiguity, you must control the technical language. Mandate the use of shared, standardized drawing formats, templates, and even specific versions of CAD software (#footnote-4){#ref-4} (e.g., SolidWorks, AutoCAD). This ensures that what your designer sees on their screen is exactly what the supplier’s engineer sees, minimizing the risk of version incompatibility or translation errors.

A single "approval" is not enough. I always implement a formal, multi-stage review process that requires mandatory sign-offs from key technical personnel on both sides at critical milestones. This creates shared accountability (#footnote-5){#ref-5} and ensures that both your engineer and their production lead have reviewed and agreed upon every technical detail before production starts.

Past performance is a strong indicator of future capability. Ask for a portfolio of successfully executed packaging designs that are similar in complexity, material, or structure to your own. This allows you to verify their historical performance and provides tangible proof that they have the experience to handle your project.

Don’t settle for a generic sample. To truly test their interpretation skills, I recommend implementing a rigorous mock-up phase based on the most complex section of your design. This physical verification (#footnote-6){#ref-6} is the ultimate test of their ability to translate your detailed specifications into a high-quality, tangible product.

For long-term or high-volume projects, providing the supplier’s key technical staff with controlled access to your PDM system (#footnote-7){#ref-7} is a game-changer. This ensures they are always working with the latest, version-controlled design files, specifications, and updates, eliminating the risk of using outdated information.

If your packaging involves proprietary methods or unique design standards, a joint training workshop is essential. This collaborative session, focused on your specific terminology, material codes, and quality expectations, ensures the supplier’s team is fully aligned with your company’s "way of working" from day one.

The first production unit is the moment of truth. A First-Article Inspection (FAI) process (#footnote-8){#ref-8}, conducted jointly by your engineer and their quality manager, is non-negotiable. This involves a meticulous, side-by-side comparison of the initial physical output against all technical specifications and tolerances, confirming that every detail has been perfectly executed.

A strong contract protects both parties. I always include a specific clause that assigns clear financial liability (#footnote-9){#ref-9} to the supplier for any production errors or waste that directly result from the misinterpretation of the provided technical specifications. This legally incentivizes the supplier to double-check every detail and ask for clarification when needed.

| Method | Stage of Engagement | Key Benefit |

|---|---|---|

| 1. Verify Certifications | Initial Vetting | Establishes baseline knowledge and professionalism. |

| 2. Technical Audit | Deep Dive Vetting | Reveals actual workflow and process discipline. |

| 3. Mandate Standards | Pre-Production | Eliminates ambiguity and technical errors. |

| 4. Multi-Stage Review | Pre-Production | Creates shared accountability and alignment. |

| 5. Review Portfolio | Initial Vetting | Proves historical capability with complex designs. |

| 6. Rigorous Sampling | Pre-Production | Physically verifies interpretation skills. |

| 7. PDM Integration | Ongoing Partnership | Ensures use of correct, up-to-date files. |

| 8. Joint Training | Onboarding / Partnership | Aligns supplier with unique design standards. |

| 9. Joint FAI | Start of Production | Confirms perfect execution of the first unit. |

| 10. Liability Clause | Contracting | Provides financial incentive for accuracy. |

When vetting a supplier, it’s essential to look beyond the surface. A truly capable partner will engage in close collaboration, proactively sharing detailed feedback to improve your design for manufacturing. Always provide them with clear technical specifications, prototypes if available, and be open to iterative feedback. Furthermore, verify their certifications and prior experience, especially for specialized applications like healthcare or fragile goods packaging. A supplier who also provides expert advice on new materials and performance trends is not just a manufacturer, but a strategic asset who can help enhance your product’s success.

Ensuring your supplier’s team can accurately interpret your packaging designs is a foundational requirement for success. By implementing these ten methods, you move from hoping for a good outcome to creating a structured process that guarantees it. This rigorous approach builds a transparent, accountable, and truly collaborative partnership, allowing you to innovate with confidence, knowing your vision will be executed flawlessly.

Ensuring your supplier’s team can accurately interpret your packaging designs is a foundational requirement for success. By implementing these ten methods, you move from hoping for a good outcome to creating a structured process that guarantees it. This rigorous approach builds a transparent, accountable, and truly collaborative partnership, allowing you to innovate with confidence, knowing your vision will be executed flawlessly.

What kind of engineering support should I expect for my custom box drawings?

You should expect comprehensive Design for Manufacturability (DFM) support (#footnote-10){#ref-10}. A skilled supplier’s engineering team will analyze your drawings to identify production hurdles, suggest structural improvements, and optimize your design for their specific machinery, ultimately saving you time and money.

How can my supplier help me optimize my design to reduce tooling and production costs?

A proactive supplier will suggest minor design modifications that could allow the use of their existing tooling, recommend more cost-effective materials that don’t compromise performance, and advise on tweaks that can increase production speed and minimize material waste.

What happens if there’s a potential structural flaw in my design file?

A competent technical team will immediately flag the issue and halt the process. They should contact you with a clear explanation of the potential flaw, its consequences (e.g., risk of damage in transit), and provide a concrete, engineered solution to correct it before moving to production.

Can they recommend better paper materials to improve my packaging’s performance?

Absolutely. An expert supplier will have material specialists who can analyze your product’s weight, shipping journey, and desired unboxing experience. They should be able to recommend specific paper grades, flute types, or coatings to improve durability, print quality, or sustainability.

1. Learn about Computer-Aided Design (CAD) for creating precise 2D and 3D digital plans. ↩︎

2. An overview of the end-to-end business process for obtaining goods and services. ↩︎

3. See how a technical audit assesses a factory’s quality systems and production processes. ↩︎

4. Explore how CAD software is used to design, draft, and produce technical documentation. ↩︎

5. Understand how shared accountability enables team agility and improves project outcomes. ↩︎

6. Learn how physical verification ensures a design’s layout works correctly before manufacturing. ↩︎

7. Discover how PDM systems centralize and manage product-related data and engineering processes. ↩︎

8. A guide to the FAI process for verifying manufacturing and engineering specifications. ↩︎

9. A clear definition of financial liability and its implications in business contracts. ↩︎

10. Explore the principles of designing products for manufacturing ease and cost optimization. ↩︎

You can leave any questions. We will see and answer you.